|

ASTM Standards |

|

NanoSolutions Testing Facilities |

|

Streamlined Testing, Expert Results |

|

NanoSolutions Testing Facilities are Streamlined to perform Testing where the results are Quantified Numbers, NOT Pass or Fail. The Standards that we follow that give such results are described on this page. |

|

ASTM Standards |

|

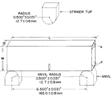

This test method establishes a procedure to measure the susceptibility of steel to a time-delayed failure such as that caused by hydrogen. It does so by measuring the threshold for the onset of subcritical crack growth using standard fracture mechanics specimens, irregular-shaped specimens such as notched round bars, or actual product such as fasteners (threaded or unthreaded) springs or components. |

|

ASTM F 1624 |

|

ASTM F 519 |

|

This test method provides an estimate for the linear elastic fracture toughness (KIC) per ASTM E1290, “Standard Test Method for Crack Tip Opening Displacement (CTOD) Fracture Toughness Measurement” |

|

ASTM E1290 |

|

For a Quote or if you have any Questions, give us a call or send us an e-mail

Phone: 714-394-3628 E-mail: Bill@NanoSolutionsUSA.com |

|

This test method describes mechanical test methods for determining the dynamic fracture toughness of materials. ASTM E604 uses impact loading to determine the dynamic fracture properties of a material. Results from this method are combined with results from ASTM E1290 to determine the Damage Tolerance Index, a factor useful for evaluating size effects on fracture toughness of products. |

|

ASTM E604 |